Eye Bolt Grade 8 with Metric Coarse Sizing

Description

Townley’s new range of Grade-8 Eye Bolts offer up to 4 times higher lifting capacity in certain applications

Geometry is designed around the DIN580 which presents a larger internal eye diameter across the range.

- Forged From High Tensile Alloy Steel

- Tempered

- Hi-Visibility Powder Coated Finish

- Manufactured exclusively from Australian Made Steel

- 100% electromagnetic crack testing to AS 1171

- Long shanks and special thread forms made to order

WLL (WORKING LOAD LIMIT)

Each Eyebolt is clearly stamped with the permitted F2 WLL.

F2 WLL – indicates safe use for non-axial lifts. This is where the load is not in line with the axis of the threaded end of the eyebolt. The following care must be taken to ensure safe use:

- The mechanical properties of the material and the condition of the tapped hole into which the eyebolt is screwed are adequate to develop the required strength.

- The tapped hole has adequate depth to accommodate the screwed shank of the eyebolt.

- The undersurface of the collar of the eyebolt and the contacting surface of the load are smooth and flat and at right angles to the axis of the tapped hole

- The eyebolt is not excessively tightened during fitting

- The thread of the eyebolt has not been damaged in a manner likely to reduce the strength

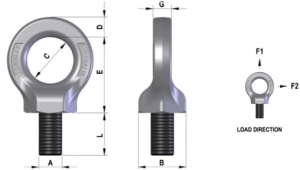

F1 WLL is not stamped on the eyebolt, however this WLL indicates loads which are in line with the axis of the threaded end of the eyebolt. F1 WLL allows up to four (4) times higher lifting capacity whilst maintaining a 4:1 design factor of safety. This higher lifting capacity is dependent on the following:

- The mechanical properties of the material and the condition of the tapped hole into which the eyebolt is screwed are adequate to develop the required strength. The minimum required strength shall be no less than 800 MPa.

- The tapped hole has adequate depth to accommodate the screwed shank of the eyebolt.

- The undersurface of the collar of the eyebolt and the contacting surface of the load are smooth and flat and at right angles to the axis of the tapped hole

- The eyebolt is not excessively tightened during fitting

- The thread of the eyebolt has not been damaged in a manner likely to reduce the strength

Specifications

| Part Number | Size (mm) |

WLL F1 (TONNES) |

WLL F2 (tonnes) |

Weight (kg) |

Dimensions (mm) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | G | L | |||||

| EB08.01ATP-T | M8 | 0.8 | 0.2 | 0.17 | 8 | 27 | 30 | 12 | 48 | 10 | 21 |

| EB10.01ATP-T | M10 | 1.0 | 0.25 | 0.17 | 10 | 27 | 30 | 12 | 48 | 10 | 21 |

| EB12.01ATP-T | M12 | 1.6 | 0.4 | 0.17 | 12 | 27 | 30 | 12 | 48 | 10 | 21 |

| EB16.01ATP-T | M16 | 4.0 | 1.0 | 0.37 | 16 | 34 | 34 | 15 | 56 | 14 | 28 |

| EB20.01ATP-T | M20 | 6.0 | 1.6 | 0.60 | 20 | 41 | 40 | 17 | 70 | 16 | 35 |

| EB24.01ATP-T | M24 | 8.0 | 2.5 | 1.10 | 24 | 50 | 50 | 20 | 85 | 18 | 42 |

| EB27.01ATP-T | M27 | 8.0 | 2.5 | 2.60 | 27 | 60 | 60 | 28 | 105 | 26 | 48 |

| EB30.01ATP-T | M30 | 12.0 | 3.0 | 3.00 | 30 | 60 | 60 | 28 | 105 | 26 | 52 |

| EB36.01ATP-T | M36 | 16.0 | 4.0 | 4.00 | 36 | 72 | 72 | 34 | 120 | 32 | 63 |