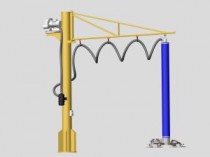

Jib Crane

Description

Jib cranes (also called Workstation Cranes) can be selected from our standard range of capacities and reaches, or can be manufactured inhouse to suit your specific requirements. Our jib cranes are available up to a lifting capacity of 5000kg, and a slewing radius of up to 8 metres. Jib cranes come in a combination of two main arm configurations, and two main support configurations.

Slewing Arm

The slewing arm comes in two designs:

- Top Braced

- Low Headroom

The Top Braced design is the lightest and therefore most cost effective type of arm. Capacities up to 500kg utilise track to help keep a low weight, low rolling friction materials handling device.

This design is commonly used on the Jumbo vacuum tube lifters.

Capacities up to 5000kg are manufactured using “I” beams. The Low Headroom design uses a horizontal “I” beam configuration, and has been manufactured to give the best effective head height in low ceiling or dimensionally restrictive environments.

Arm Support

The arm supports come in two designs:

- Free Standing

- Column Mounted

The Free Standing Jib Crane comes with an arm of your choice, and a post which is bolted to a concrete floor. Depending on the capacity of the crane, and the reach of the arm, the crane is either fixed to the concrete using high capacity chemically set anchors, or a new concrete footing is poured, with bolts set into the concrete. The Column Mounted design is for fixing jib arms to an existing building column. The mounting bracket can be made to suit all applications, with a variety of fixing methods. This configuration is cost effective as a support post is not needed.

Specifications

Contact our sales team for further details